Dr. Loose GmbH is a globally active engineering services company in the field of

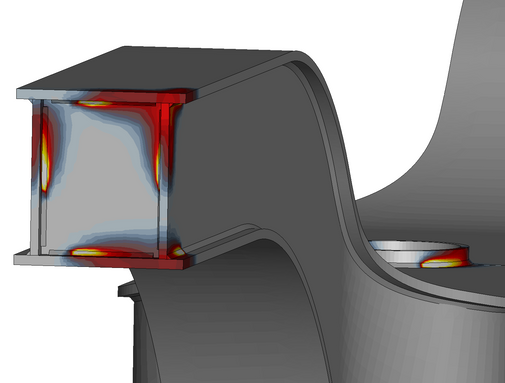

Finite Element Analysis for welding simulation, manufacturing simulation, thermal simulation and welding consulting.

We draw on more than 20 years of experience in our special field, the numerical manufacturing simulation for welded and heat treated components.

With manufacturing simulation, we can support our customers in the product development process from the early stages of planning by providing our expertise to solve manufacturing-specific challenges.

We are happy to numerically validate your welded assembly before the first arc is ignited.

Our engineers solve welding problems for you with the help of simulation methods and support you in planning and designing your welded structures, determining the welding sequence, the clamping and tacking concept and the heat guidance.

Our welding engineers attach great importance to process-reliable production with optimum results for minimum tolerance deviation.

With our many years of experience in solution strategies for industrial applications and scientific research results in the field of welding optimization, we are a competent partner for the construction industry, light and heavy engineering, shipbuilding, plant engineering, rail vehicle construction and the automotive industry.

In addition, our welding engineers offer solution-oriented consulting for development engineers and welding technicians from industry and welding companies.

layout of the assembly of welded modules,

multi-stage assembly, design of clamping

and tacking concepts, weld sequence planning, design and evaluation of compensation measures, distortion management and distortion minimization as well as process chain simulation.

welding consulting

process layout

thermal management

material selection

numerical analysis of welded

or heat-treated components

distortion analysis

distortion origin analysis

residual stress analysis

microstructure analysis

crack risk evaluation

Design of welds, considering the applied heat, heating of thermal sensetive compnents, evolution of microstructure in the heat affected zone, material recommendation.

Customer related software

tools for automatization

add ons

special application

Custoer related research and development

development of methods for simulation applications

© Dr. Loose GmbH, alle Rechte vorbehalten | Impressum | Datenschutz | Rechtliche Hinweise