Over 40 years of scientific work have been combined in a powerful simulation tool developed specifically for welding, heat treating and casting by Goldak Technologies Inc. in Ottawa, Canada.

"The primary aim of the work is to transfer this technology from the research specialists who are devoleloping it to the engineers who must apply it in the design and production of welded structures" [Goldak 1985].

This vision of John Goldak leads to designer-assisted software that meets the main problems and requirements for the numerical code of a manufacturing simulation tool:

all this combined with an easy-to-use user interface that automates as many steps as possible.

Goldak - VrSuite contains the following modules:

Goldak Vr-Suite takes into account all physical phenomena required for the calculation. The complex system is solved by different coupled and parallel solvers in a fully transient 3D calculation:

extended by a simulation on the micro-scale for microstructure and

Fatigue analysis as well as for optimization analysis.

The VrSuite code uses GPU technology.

The results can be used as the initial state for the next simulation step in all modules. In addition, calculation results from different external software solutions can be imported. It is also possible to export the VrSuite results for various solvers. This ultimately enables process chain simulation, which is essential for manufacturing simulations.

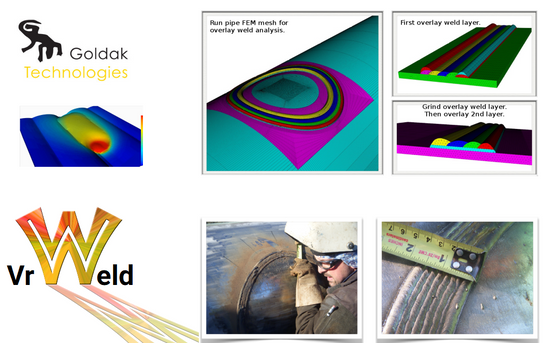

As a rule, welding simulation falls back on commercial multi-physics codes that are extended by welding-specific additional functions. The overhead that such extended codes carry in welding simulation quickly leads to very slow and unstable calculations. With VrWeld, this is fundamentally different: this code has been developed and optimized by John Goldak and his team for the special requirements of welding simulation from the very beginning.

Each physically independent task area is controlled by an independent solver. This increases the performance.

Goldak Vr-Weld is a self-contained simulation tool. Starting from the CAD geometry of your components, the welding procedure specification (WPS) and the weld sequence plan, you create in VrWeld the calculation model for the weld assembly of all possible welded structures. In doing so, you can create calculation models for the overall structure:

as well as partial models for welding process simulation or micro models for microstructure simulation:

VrWeld is designed for both single-pass and multilayer welded structures. VrWeld is the only welding software that has automated filler metal meshing tools for multilayer welding. Based on the parameters of the welding instruction, the weld cross-sections of the individual beads are reproduced with surface accuracy. In addition, with the help of the new Goldak heat source WeldPoosQS, you can precalculate the bead geometry of a multilayer weld and include it in your simulation model.

VrWeld excels in stable and fast calculation of weld models. Especially multilayer welds, build-up welds with many beads or repair welds are no big challenge for VrWeld - neither in model creation nor in calculation - thanks to special subdomain algorithm and GPU support.

VrWeld contains a material database for many common steel and aluminum alloys. User-specific data can be added or calculated with the integrated material simulation.

Wärmebehandlung: das ist Metallurgie, Diffusion, Thermik, Mechanik und Gefügeumwanldung die gekoppelt und interagierend während des Prozesses ablaufen.

Die Idee von John Goldak: Eine Simulationssoftware muß diese Phänomene in sich geschlossen abbilden können. Mit VrHeatTreat haben Goldak und sein Team dies umgesetzt.

Processes:

Quenching media:

Main functionalities:

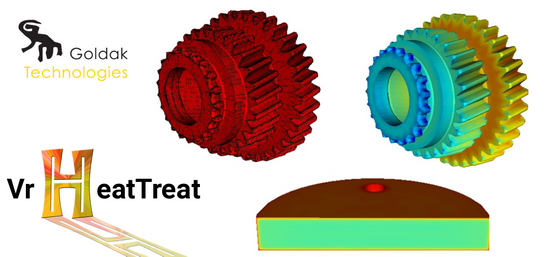

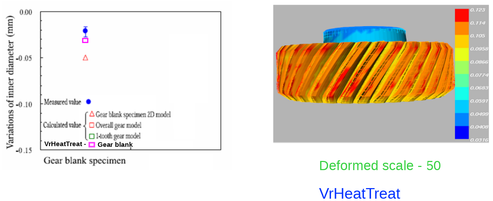

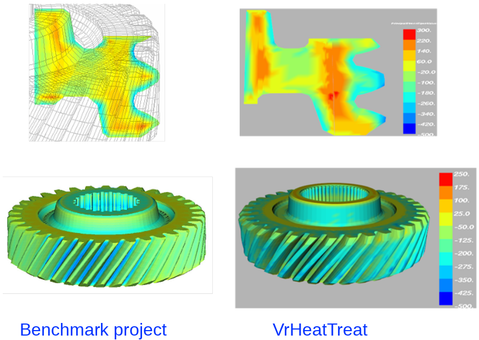

The construction of the complex simulation model is automated as far as possible. Significant time savings are achieved by the meshing algorithm of VrHeatTreat, which was especially developed for the heat treatment problem. This enables the user to create calculation models for gears in less than one hour.

The material properties are captured by chemical analysis. The carbon distribution in the workpiece is determined by diffusion simulation. From this, VrHeatTreat calculates the microstructure transformation and determines the strength change of the carburized zone.

With VrHeatTreat, you can optimize the geometry for minimum heat distortion, determine the hardening depth, and verify that carburization also occurs in recessed edges and corners as desired.

Is it possible to weld without distortion?

Is it possible to weld without residual stresses remaining?

Yes, it is possible with VrOptimizer.

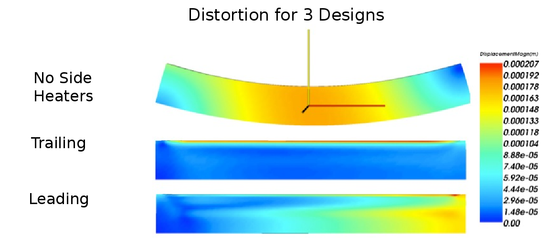

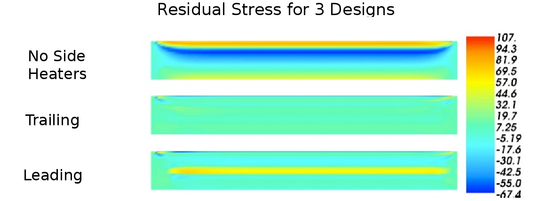

Some researchers have investigated how additional heat sources, additional cooling sources, or metallurgically special filler material can fully compensate for the distortion of a single weld. The position and power of the additional source is crucial. Only a certain position of the additional source and a defined power lead to success.

There are a large number of possible parameter settings - the "try and error" method is of little help. To solve this optimization problem John Goldak and his team have developed VrOptimizer. VrOptimizer is based on an efficient optimization algorithm according to Kriging with which it is possible to reach the goal from a small number of calculated variants [1].

With VrOptimizer you are able to design your welding process almost free of distortion and with low residual stress.

[1]: Chernov, S. ; Goldak, J.: Can a weld in welded structure be made with zero residual stress? In: Proceedings of the ASME 2015 Pressure Vessels & Piping Division Conference, 19-23.7.2015, Boston, Massachusetts, USA.

Welded joints are critical points of a structure and often the areas where a structure fails. Alternating loads tend to cause more damage at the same load level than static loads.

WithVrFrac you can calculate the crack propagation under dynamic loading.

In welded joints, welding residual stresses are superimposed on the load stresses. The interface between VrFrac and VrWeld allows a holistic view of the problem. On the 3D model, the residual stress state is calculated with the weld structure simulation and transferred to the local model for fatigue analysis. The local load stresses are determined from the applied load spectrum. Crack initiation and propagation are calculated via the damage algorithm.

More info: Fracture mechanics you can understand

© Dr. Loose GmbH, alle Rechte vorbehalten | Impressum | Datenschutz | Rechtliche Hinweise