Advanced

Fabrication Engineering for

Welded Structures

Welding Simulation with FabWeld

FabWeld is a development environment for the optimal application of the LS-DYNA code for the calculation of all thermal joining processes using the finite element method for highest precision

with the help of the welding structure simulation.

With FabWeld you simulate all processes of arc and beam welding as well as brazing.

Of course, you can calculate upstream and downstream heat treatment with FabWeld. Investigate different variants for cooling and stress releasing. Analyze the mechanical stress of welded structures and create accurate simulation models.

Our advantages:

FabWeld is a development environment for the goal-oriented creation of simulation models for single- and multi-stage weld assembly.

The software also supports heat treatment processes that are either coupled with the weld assembly, for example as post-weld heat treatment, or applied as an upstream process for individual components.

The design is process chain oriented and can integrate simulation results from an upstream forming simulation as well as output calculation results for a downstream forming simulation, paint drying simulation or strength analysis.

FabWeld also allows the analysis of service and ultimate load conditions. Loads, pressures, constraints or temperature stresses can be applied.

.

During the development of FabWeld, care was taken to ensure that welding simulation models with a large number of weld beads can be created in a short time.

The program supports 2D cross-section models, 3D solid element models, 3D shell element models and hybrid models in order to optimally meet the requirements of the respective calculation tasks.

FabWeld® has interfaces to Sorpas®, SimWeld®, WeldWare® JMatPro® DynaWeld® und Sysweld.

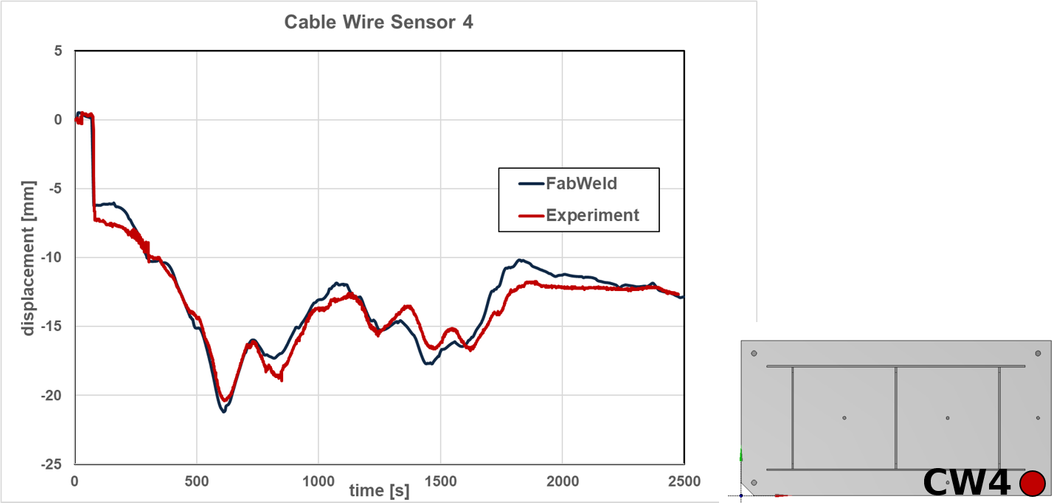

With the reliable FabWeld analysis tool, all relevant physical effects are mapped. Thus, welding distortions are accurately predicted, not only as a final state but during the entire welding process.

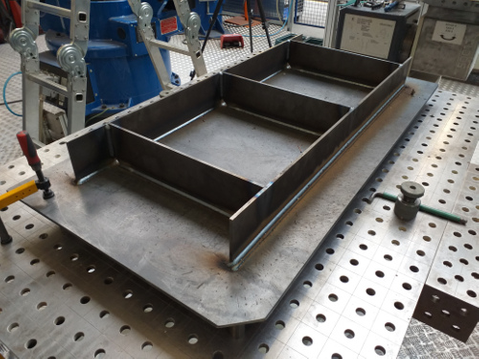

FabWeld provides very good correlation between calculated vertical distortion (blue) and measured vertical distortion (orange):

© Dr. Loose GmbH, alle Rechte vorbehalten | Impressum | Datenschutz | Rechtliche Hinweise