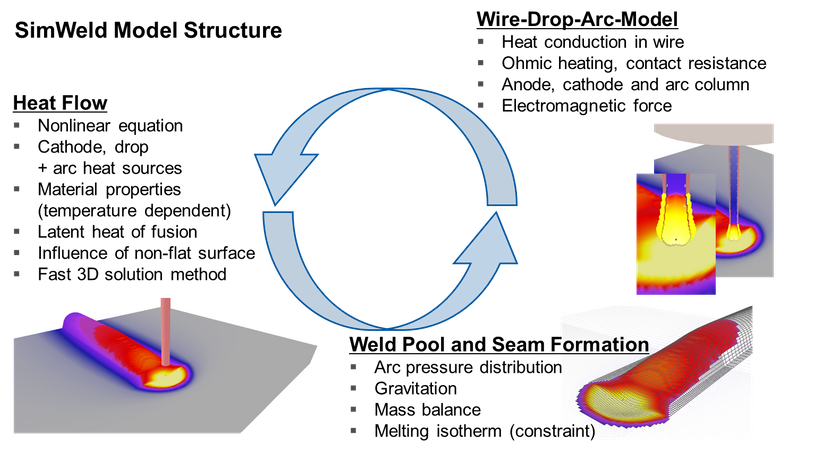

With SimWeld® you can use the setting parameters at the welding current source to calculate the weld pool geometry.

With SimWeld®, you control penetration, seam protrusion and the formation of penetration notches. You avoid seam defects by selecting optimum setting parameters.

You can further use the results of your SimWeld® calculation in the weld structure simulation.

SimWeld® calculation results are available in less than two minutes!

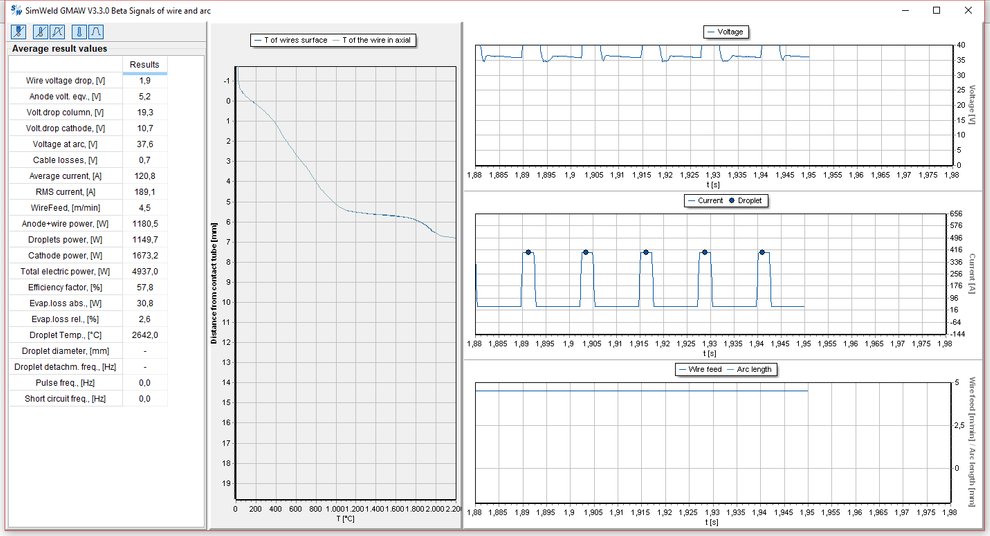

SimWeld® uses the setting parameters of the welding current source to calculate current and voltage profiles, tropical detachment, component heating and weld pool formation from the setting parameters of the welding current source.

You get the temperature-time curve as a result of the calculation at any position.

The melt pool and the heat-affected zone are displayed in cross-section.

Intelligent solver algorithms enable a fast calculation.

With SimWeld® you can calculate the heat input and export the equivalent heat source for a weld structure simulation. For this purpose, SimWeld® offers modified Goldak heat sources, which were developed as part of a research project.

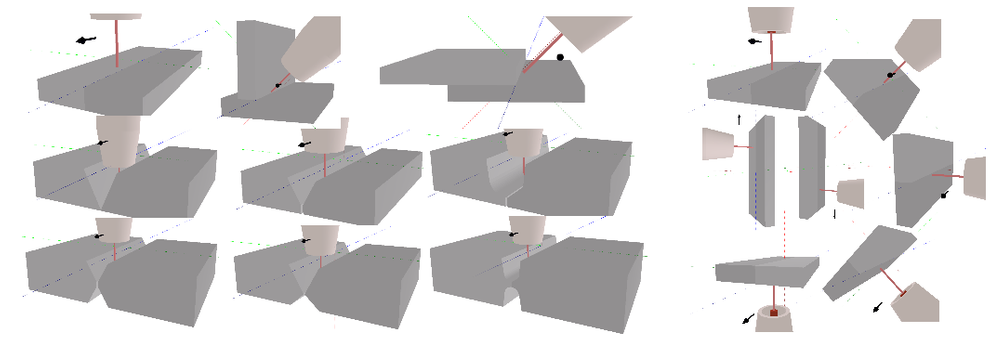

With SimWeld® you can display all welding positions and torch positions.

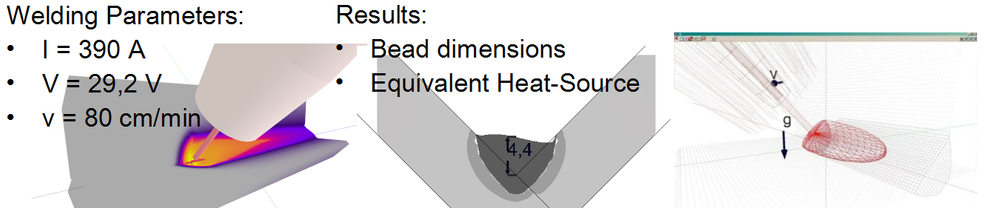

Example calculation with SimWeld®.

left: simulation, middle: depiction of the weld pool, right: equivalent heat source

In diesem Beispiel wird der Spannungs- und Stromverlauf während der Berechnung dargestellt.

With SimWeld® you can display all welding positions and torch positions.

© Dr. Loose GmbH, alle Rechte vorbehalten | Impressum | Datenschutz | Rechtliche Hinweise